E-Commerce Notes

Unit-3

Lecture-1

Value Chain

·

The

value chain is a concept from business management that was first described and

popularized by Michael Porter in his 1985 best seller, Competitive Advantage:

Creating and Sustaining Superior Performance.

·

A

Value Chain is a chain of activities for a firm operating in a specific

industry.

·

Products

pass through all activities of the chain in order and at each activity the

product gains some value. The chain of activities gives the products more added

value than the sum of the independent activities value.

Here we have shown just a basic value chain flow of an Automobile Industry.

Here we have shown just a basic value chain flow of an Automobile Industry.

·

A

diamond cutter, as a profession, can be used to illustrate the difference of

cost and the value chain. The cutting activity may have a low cost, but the

activity adds much of the value to the end product, since a rough diamond is

significantly less valuable than a cut diamond.

·

The

value chain framework quickly made its way to the forefront of management

thought as a powerful analysis tool for strategic planning. Value chain

analysis has also been successfully used in large Petrochemical Plant

Maintenance Organizations to show how Work Selection, Work Planning, Work

Scheduling and finally Work Execution can (when considered as elements of

chains) help drive Lean approaches to Maintenance.

Porter’s Value Chain

Model

The idea of

the value chain is based on the process of organization, the idea of seeing a

manufacturing (or service) organization as a system, made up of subsystems each

with inputs, transformation processes and outputs. Inputs, transformation

processes, and outputs involve the acquisition & consumption of resources-

money, labour, materials, equipment, buildings, land, administration and

management. How value chain activities are carried out determines costs and

affects profits.

Most

organizations engage in hundreds, even thousands of activities in the process

of converting inputs to outputs. These activities can be classified generally

as either primary or support activities that all businesses must undertake in

some form.

According to Porter (1985), the

primary activities are:-

Ø Inbound Logistics: involve relationships with suppliers and include all the activities

required to receive, store & disseminate inputs.

Ø Operations:

are all the activities required to transform inputs into outputs (products

& services).

Ø Outbound Logistics: include all activities required to

collect, store & distribute the output.

Ø Marketing & Sales: activities inform buyers about products & services, induce buyer to

purchase them and facilitate their purchase.

Ø Service:

includes all the activities required to keep the product or service working

effectively for the buyer after it is sold and delivered.

Support Activities are:-

Ø Procurement:

is the acquisition of inputs, or

resources, for the firm.

Ø Human Resource Management: consists of all activities involved in recruiting, hiring,

training, developing, compensating and dismissing or laying off personnel.

Ø Technological Development: pertains to the equipment, hardware, software, procedures

and technical knowledge brought to bear in the firm’s transformation of inputs

into outputs.

Ø Infrastructure:

Serves the company’s needs & ties its various parts together, it consists

of functions or departments such as accounting, legal, finance, planning,

public affairs, government relations, quality assurance & general

management.

Fig

PORTER’S GENERIC VALUE CHAIN

Linked Value Chains

Value chain

activities are not isolated from one another. Rather, one value chain activity

often affects the cost or performance of other ones. Linkages may exist between

primary & support activities. Interrelationships among business units form

the basis for a horizontal strategy. Such business unit interrelationships can

be identified by a value chain analysis.

Inbound Logistic- From Suppliers

Inbound Logistic- From Suppliers

Outbound Logistic- From Customers

E-Commerce enhances value chain by

providing:-

Ø Electronic Value Chain: through electronic value chain, e-commerce enhances

business by supporting:

·

Reduced

time frame

·

Changed

Cost Structures

Ø Re-engineered value: Re-engineered value chain, e-commerce enhances

business by supporting:

·

Just-in-time

Manufacturing

·

Quick

response supply

·

Efficient

document processing

Ø Competitive Advantage: E-Commerce supports a company for gaining

competitive advantage.

E-Commerce Notes

Unit-3

Lecture-2

Competitive Advantage

·

A

firm is said to possess a competitive advantage over its rivals, if it sustains

profit that exceed the average for its industry.

·

The

goal of much of business strategy is to achieve a sustainable competitive

advantage.

·

Michael

Porter identified two basic types of Competitive advantage:

Ø Cost Advantage

Ø Differentiation Advantage

Cost Advantage:

Cost advantage exists when the firm is able to deliver the same benefits as

competitors but at a lower cost.

Differentiation Advantage: Differentiation advantage exists when the firm is able to

deliver benefits that exceed those of competing products.

Cost and differentiation advantages

are known as potential advantages since they describe the firm’s position in

the industry as a leader in either cost or differentiation.

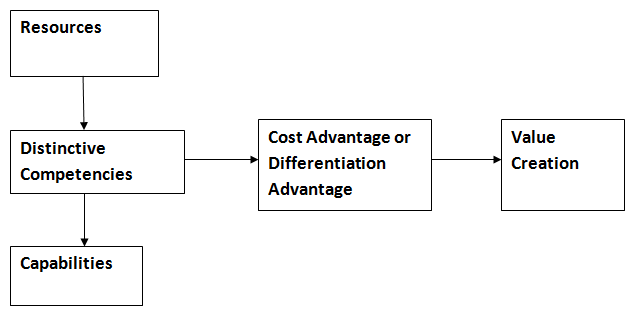

A resource based view emphasizes that

a firm utilizes its resources and

capabilities to create a competitive advantage that ultimately results in

superior value creation.

Resources & Capabilities:

According to the resource based view,

in order to develop a competitive advantage the firm must have resources and

capabilities that are superior to those of its competitors.

Resources: are

the firm-specific assets useful for creating a cost or differentiation

advantage and that few competitors can acquire easily.

Capabilities:

refer to the firm’s ability to utilize its resources effectively. An example of

a capability is the ability to bring a product to market faster than

competitors. The firm’s resources & capabilities together form its

distinctive competencies.

Model of Competitive

Advantage

Value Creation: The firm creates value by performing a series of activities that Porter

identified as the value chain. Superior value is created through lower costs or

superior benefits to the customers.

The Principle of Competitive Advantage --

Success is based on inventing an

offering that addresses a real scarcity in the world, charging a price for it,

and inventing a way of making it available that is cheap enough to leave a high

margin.

Elements of Competitive Advantage –

Uniqueness -

finding unique opportunities and solutions is about imagination, insight,

foresight, and the courage to pursue it. Unique is new, different, but most

important of all, untested and unproven. By the time a unique solution is

validated as profitable, it is no longer unique for the next company. Also, if

it is a unique business model or business capability, it is likely

unapproachable, in the short-term, by competitors.

Strategic Focus

- Strategic focus comes from marrying

distinctive competency and purpose to form a superior value proposition.

Strategic focus is about developing a longer view of competitive advantage with

a combination of purpose, competency, and value proposition. This creates an

internal environment that has the confidence and implicit support to continue

to perfect and develop that focus through creating stronger competencies and

further perfecting the value proposition.

Strategic Intent/Vision/BHAGs - Strategic intent challenges and guides the organization to

achieve the unachievable by having a clear focus on outlandish objectives which

require the development of new capabilities to achieve.

Innovation -

Innovation is inventiveness put into profitable practice. In an evolving

economy, the business organization must innovate at a rate that meets or

exceeds its environment in order to sustain a competitive advantage.

Continual Innovation - Making innovation as an ongoing process on all fronts.

Democratic Principles - Democratic principles are needed to fully engage the active

participation of diverse thinkers from across the organization. Broad and

diverse participation improves innovation.

Strategic Management as a self-improving learning process - Strategic management must become,

amongst other things, a learning and self-improvement process for the

organization.

Dynamic Capabilities - Sustainable competitive advantage is ultimately based on dynamic

capabilities, the capability to produce and utilize new capabilities on a

continuous basis.

E-Commerce Notes

Unit-3

Lecture-3

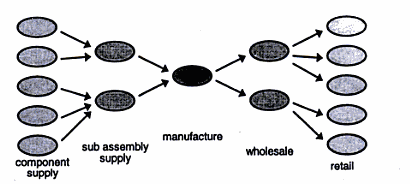

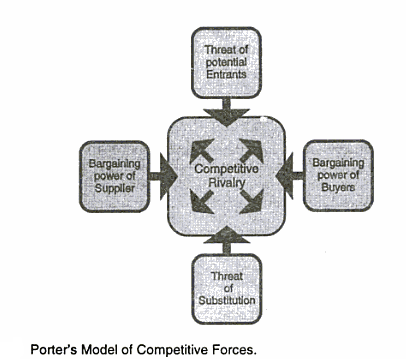

Porter’s Five Forces Model:

Michael Porter described a concept

that has become known as the “five forces model”. This concept involves a

relationship between competitors within an industry, potential competitors, suppliers,

buyers & alternative solutions to the problem being addressed.

·

Threat of Potential Entrants: The threat of new entrants relates

to the ease with which a new company or a company in a different product area

can enter a given trade sector. Barrier to entry into a particular market

include the need for capital, knowledge and skills. The barriers to entry for e.g. to the vehicle

assembly sector are massive; to start building cars there is the need to

develop a new model range, build a car assembly plant, contract a large number

of component suppliers and sign up a dealer network. Getting into business in

building personal computers is, in contrast, much easier; the components are

readily available and there is not the same need for investment in product

development or large scale production facilities before the company makes a

start.

·

Threat of Substitution: Substitution is a threat to

existing players where a new product becomes available that supplies the same

function as the existing product or service. The classic examples are the

(partial) substitution of natural fibres such as cotton and wool by synthetic

fibres or the replacement of glass bottles by a plastic alternative in some

sectors of the packaging industry. Existing players can protect themselves by

keeping their product up-to-date.

·

Bargaining power of Buyers: For a business to be profitable the

cost of producing and distributing its product

has to be less than the price it can fetch in the market place. Where

there are a number of competitors in the market or a surplus of supply the

buyer is in a strong position to bargain for a low price and for other

favorable conditions of trade.

·

Bargaining power of Suppliers: The organization, while trying to

get an adequate price from its buyers, will be looking to get favorable terms

from its own suppliers at the next stage along the value chain. The

organization’s ability to get a good deal is the mirror image of its position

with its buyers. If the supply is plentiful and/or there are several suppliers

it should get a good price. If the product is scarce or the number of suppliers

that are able to meet its need is limited then the supplier is in a more

favorable position.

·

Competition between existing players: The final force is the completion

between existing players in the market. The competition is to get the buyers

and to trade at a price that produces an acceptable profit. That competition is

won on the basis of the generic competitive advantage of cost or

differentiation. The competitive position of each organization is determined by

the deal it is able to make with the suppliers.

Important

Points of Value Chain:

1. The Organization need to establish which of its inter

organizational relationships add to its competitive advantage & which fail

to achieve appropriate levels of quality & price.

2. The Linkages in the value system have to be managed.

3. The Physical Linkage involves good handling, transport

& warehousing

4. Value chain must be clear & understandable.

5. The essential stages of a value chain are: Pre-sale,

Execution, settlement & after-sales.

E-Commerce Notes

Unit-3

Lecture-4

Business Process Reengineering (BPR)

v Business Process Re-engineering is

the fundamental rethinking and radical re-design of business processes to

achieve dramatic improvements in critical contemporary measures of performance

such as cost, quality, service and speed.

v BPR means not only change but

dramatic change & dramatic improvements.

v BPR involves the overhaul of

organizational structures, management systems, job descriptions, performance

measurements, skill development, training and most importantly the use of

information technology.BPR impacts every aspect of how the organization runs

its business.

v Change on this scale can cause

results ranging from enviable success to complete breakdown & failure.

v A successful BPR can result in

dramatic performance improvements, increase in profits, better business

practices, enormous cost reductions, dramatic improvements in productivity

& so on.

Different Phases of BPR

·

Begin

Organizational Change

·

Building

the reengineering organization

·

Identifying

BPR opportunities

·

Understanding

the existing process

·

Re-engineering

the process

·

Blueprint

the new business system

·

Perform

the transformation

1.

Begin Organizational Change:

Ø Assess the current state of

organization.

Ø Explain the need for change.

Ø Illustrate the desired state.

Ø Create a communication campaign for

change.

2.

Building the reengineering

organization:

Ø Establish a BPR organizational

structure.

Ø Establish the roles for performing

BPR.

Ø Choose the personnel who will

reengineer.

3.

Identifying BPR opportunities:

Ø Identifying the high level process.

Ø Gather performance metrics within &

outside industry.

Ø Prioritize selected process.

Ø Consult with customers for their

desires.

4.

Understanding the existing process:

Ø Model the current process.

Ø Understand how technology is

currently used.

Ø Understand how information is

currently used.

5.

Reengineer the process:

Ø Question current operating

assumptions.

Ø Evaluate the impact of new

technologies.

Ø Consider the perspective of

stakeholders.

6.

Blueprint the new business system:

Ø Define the new flow of work.

Ø Model the new process steps.

Ø Model the new information

requirements.

Ø Describe the new technology

specifications.

7.

Perform the transformation:

Ø Develop a migration strategy.

Ø Reallocate workforce.

Ø Educate staff about the new process.

Ø Implement in an iterative fashion.

Challenges in BPR

§ Unfortunately, all BPR projects are

not as successful as those described.

§ Most of the BPR projects will fall

short of expectations.

§ Companies that begin BPR projects

face many of the following challenges:-

« Resistance from employees.

« Changing the traditional ways of

doing things.

« Time Requirements (BPR is a lengthy

process, almost always taking two or more years to complete).

« High cost of BPR.

« Manpower reduction (BPR often results

in employees being laid off).

Maximizing Chances for BPR Success

The

guidelines that will help in maximizing chances for success in a BPR effort

are:-

® Realize that not every company needs

to re-invent.

® Expect strenuous resistance &

manage it properly.

® Get top management support.

® Communicate with employees to prevent

rumors & misunderstandings.

® Create an atmosphere of trust &

co-operation.

® Change the way employees are

evaluated & rewarded to motivate them to support the system.

® Staff the project with the best

people & provide them with resources they need.

® Make sure the employees are adequately trained

on how to use the new system.

® Go for small success at first. Go for

more dramatic projects once you have gained some experience in BPR.

E-Commerce Notes

Unit-3

Lecture-5

Business Process Management (BPM)

v Business Process Management has been

referred to as a “holistic management” approach to aligning an organization’s

business processes with the wants and needs of clients.

v BPM uses a systematic approach in an

attempt to continuously improve business effectiveness and efficiency while

striving for innovation, flexibility and integration with technology

v As a managerial approach BPM sees

processes as strategic assets of an organization that must be understood,

managed & improved to deliver value added products & services to

clients.

v BPM is the discipline of modeling,

automating, managing, monitoring and optimizing business processes to increase

profitability.

Business Process

A business process is a set

activities required to accomplish a common goal. The activities may be

performed by people or systems and are completed either sequentially or

simultaneously. It is best to think of a business process as the way that work

should be performed.

BPM Life Cycle

BPM is a discipline consisting of 5

phases:-

« Model

« Automate

« Execute

« Monitor

« Optimize

1.

Model: The first phase of BPM is to create

a model. e.g. a globe is a model of the planet earth. During model phase, we

begin by creating a high level diagram of the process. Initially, the goal to

gather just enough detail to understand conceptually how the process works and

the main steps involved without being distracted by the fine detail of how it

will be implemented.

2.

Automate: During the Automate phase, the

model is expanded to create the specific set of instructions, form details and

rules needed to run the process. It is at this point where discussion about how

to specifically implement the processes is made. e.g. while a globe is a model

of the earth, a map provides the detailed directions between two cities &

helps you decide which route to travel.

3.

Execute: The Execute phase of BPM consists

of interpreting the instructions created during the Automate phase to manage

the flow of work from the beginning of the phase until its completion. Within

BPM software, the workflow engine is responsible for creating tasks and

automatically directing them to the right people or systems based on the

process rules much like the way a GPS system provides you with step-by-step

driving instructions to your destination.

4.

Monitor: The monitor phase is where process

performance is measured, tracked & reviewed for potential improvements.

e.g. identifying that travel time has increased by 30% might cause you to test

an alternative route to avoid the new traffic signals.

5.

Optimize: During the optimize phase, managers

use data and lessons learned from manage phase as a foundation to change the

process. Optimization may include such things as enhancing the data collection forms,

adding or removing tasks, automating steps that were previously completed

manually or modifying the reports generated. The goal of the optimize phase is

to identify changes that will improve the process.

E-Commerce Notes

Unit-3

Lecture-6

Customer Relationship Management (CRM)

v CRM is a widely implemented strategy

for managing a company’s interactions with customers, clients & sales

prospects. It involves using technology to organize, automate & synchronize

business processes.

v The overall goal is to find, attract

and win new clients, nurture & retain those the company already has &

reduce the costs of marketing and client service.

v CRM is an iterative process that

turns customer information into positive customer relationship.

v Some of the leading vendors of CRM systems are Siebel

Systems, Oracle, and People Soft.

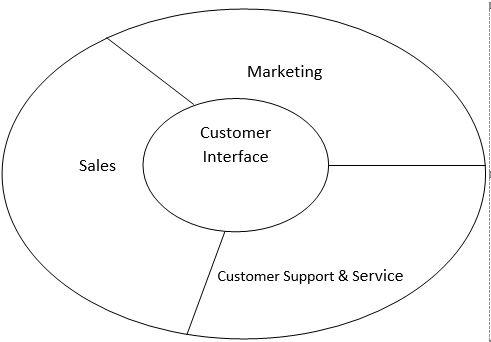

Process of CRM

Goals of CRM

·

Provide

better customer service.

·

Make

call centers more efficient.

·

Increase

sales.

·

Simplify

marketing & Sales processes.

·

Discovering

new customers

·

Increase

the quality of Information.

·

Improve

customer retention.

Three Fundamental Components of CRM

·

Operational: Automation of basic business processes

(marketing, sales, service).

·

Analytical: Analysis of customer data &

behavior using business intelligence.

·

Collaborative: Communicating with clients.

Functions of CRM

« Identify factors important to

clients.

« Promote a customer oriented

philosophy.

« Adopt customer based measures.

« Provide successful customer support.

« Handle customer complaints.

« Track all aspects of Sales.

Uses of CRM

® Providing on-line access to product

information & technical assistance around the clock.

® Identifying what customer’s value

& devising appropriate service strategies for each customer.

® Providing mechanisms for managing

& scheduling follow-up sales calls.

® Tracking all contacts with a

customer.

® Identifying potential problems before

they occur.

® Providing a user-friendly mechanism

for registering customer complaints.

® Providing a mechanism for handling

problems & complaints.

® Providing a mechanism for correcting

service deficiencies.

® Storing customer interests in order

to target customers selectively.

® Providing mechanics for managing

& scheduling maintenance, repair & ongoing support.

Application Components in CRM systems

CRM supports critical Marketing

processes including the following:-

Ø Technology enabled selling

Ø Marketing Resource Management

Ø Segment and List Management

Ø Call Center Management

Ø Campaign Management

Ø Field Service Management

Ø Trade Promotion Management

Ø Lead Management

Ø Marketing Analysis

E-Commerce Notes

Unit-3

Lecture-7

Supply Chain

·

A

supply chain is a system of organizations, people, technology, activities,

information and resources involved in moving a product or service from supplier

to customer.

·

Supply

chain activities transform natural resources, raw materials and components into

a finished product that is delivered to the end customer.

·

In

sophisticated supply chain systems, used products may re-enter the supply chain

at any point where residual value is recyclable.

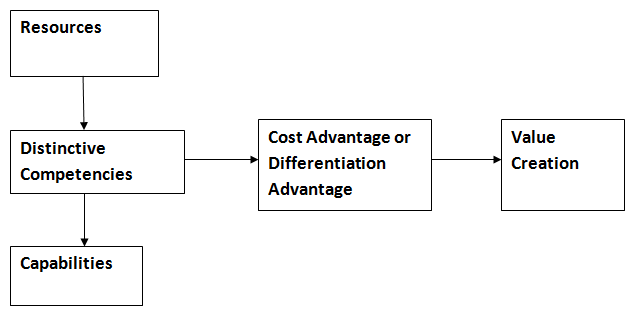

Supply Chain Management(SCM)

·

Supply

Chain Management is the oversight of materials, information & finances as

they move in a process from supplier to manufacturer to wholesaler to retailer

to consumer.

·

SCM

involves coordinating & integrating these flows both within & among

companies.

·

SCM

enables collaboration, planning, execution & coordination of the entire

supply chain, empowering companies to adopt their supply chain processes to an

ever changing competitive environment.

·

With

better synchronization across the entire supply chain, the business partners

achieve the following major benefits:-

Ø Lower Inventories & therefore

lower financing costs

Ø Shorter receivable cycles

Ø Optimal use of production resources

& costly workforces

Ø Faster response to market changes

Ø Greater satisfaction & loyalty

among customers

Ø Greater profitability

·

The

military was one of the first organizations to recognize supply chains & to

manage them during World War II.

·

The

SCM systems have become more efficient & intelligent with the use of

computers, artificial intelligence & other advancements in the field of

information technology.

·

SCM

solution transform traditional supply chains from linear, sequential steps into

an adaptive supply chain network in which communities of customer-centric,

demand driven companies share knowledge, intelligently adapt to changing market

conditions & proactively respond to shorter, less predictable life cycles.

·

Today

almost all organizations-military, manufacturing, service industries, retailers

& so on use SCM systems to improve their efficiency & effectiveness.

Advantages of Supply Chain Management

« Supply Chain Planning & Collaboration: Supply chain planning functionality

enables you to maximize return on assets & ensures a profitable match of

supply & demand.

« Supply Chain Execution: SCM enables you to carry out supply chain planning &

generate high efficiency at the lowest possible cost.

« Supply Chain Visibility Design & Analytics: SCM gives you network-wide

visibility across your extended supply chain to perform strategic as well as

day-to-day planning.

« Business Benefits: SCM can help you transform linear supply chain into an adaptive network

with the following benefits:-

§ Faster response to changes in supply

& demand.

§ Increased customer satisfaction.

§ Compliance with regulatory

requirements

§ Improved Cash flow

§ High margins

§

Greater

synchronization with business priorities

Just In Time (JIT)

·

JIT

means to produce goods and services when needed, not too early and not too

late. It is time based and often has quality and efficiency targets.

·

It

is a Japanese production management philosophy since 1970s, which allows having

the right items of the right quantity & quality, in the right place and at

right time. This is hand to mouth approach to production. The primary goal of

JIT is to achieve zero inventories within the organization as well as

throughout the entire supply chain.

·

The

JIT system uses the PULL method of scheduling material flow.

·

A

JIT system aims to make goods available just-in-time, and these cab be parts, products

or sub-assemblies and achieve some of the following benefits:-

§ Increased Flexibility

§ Parts Reduction

§ Increased Quality

§

Simplicity

of System

To achieve the aims of JIT a

disciplined approach is needed which incorporates three principles applied to the

organization:-

Ø Elimination of Waste

Ø Total Quality Management

Ø Total Employee Involvement

Elimination of Waste: Waste elimination is basically removal of any activity that is not

value-added, but first it has to be identified. These activities don’t increase

product value and are costly to the company. Examples of non-value added

activities include traditional production methods, i.e, inspection of parts,

holding stock inventories, time etc.

Waste can be eliminated from these

activities by removal of defects and by not over producing hence,

make-to-order.

Total Quality Management: TQM eliminates waste by eliminating defects. In a JIT

environment, the aim is to prevent defects from occurring and this is achieved

by detecting problems at their source. The whole organization is involved in

the process, right from the stages of manufacturing, product development and

purchasing. Manufacturing uses statistical process control (SPC) and in-process

testing (to allow detection at source), while product development ensures that

new products can be manufactured to specification. Purchasing makes sure that

the parts that are bought are of required quality.

Total Employee Involvement: Total employee involvement has management providing the

leadership which result in employees wanting to be involved in the processes.

Opportunity is provided through education & training & work teams.

Benefits of JIT

® Increased Flexibility: A flexible workforce means that the operators must be multi-skilled

which is done through training. The worker should be free to move from low

demand to high demand areas.

® Parts reduction:

JIT continuously seeks to reduce inventory levels of raw materials, work in

progress and finished goods. Lower inventory means less space & less chance

of the product being obsolete, damaged or spoiled.

® Increased Quality: When operating a JIT system, disruption has a major impact, so quality

problems need to be eliminated. Benchmarking Quality Function Deployment and

service design can be used for service operations. Since employees need to

learn the value of providing defect free services.

®

Simplicity of System: Product mix or volume changes as

planned by the Master Production Schedule (MPS) can be accomplished by

adjusting the no. of cards in the system. Production orders are prioritized by

the cards on a post. Production orders for parts that are running low are moved

in front of parts that have more supply.

Potential Pitfalls of JIT

® Many companies fail to understand

what JIT is and what it can mean to them because they fail to implement it

properly. Most importantly, they need to be aware of the tasks, resources, time

scale and costs. For this, the system will need the full backing of the top

management.

®

The

JIT will also fail, if an adequate education programme is not provided. If

careful planning of process & control improvements are not strictly

followed, they will result in JIT not been realized. The planning stage will

require dedication & time and may also require the assistance of an

external consultant(s).

PUSH & PULL System of Production

The term PUSH and PULL are used to

describe two different systems for moving work through a production process.

In traditional environments, a PUSH

system is used. When work is finished at a work station, the output is pushed

to the next station or in the case of final production it is pushed on to the

final inventory.

Conversely, in a PULL system-each

work station pulls the output from the preceding station as it is needed; the

output of final operation is pulled by the customer demand or the master

schedule. Thus in a PULL system, work moves on in response to demand from the

next stage in the process, whereas in a

PUSH system, work moves on as it is completed without regard to the next

station’s readiness for the work. Consequently work may pile up at workstations

that fall behind schedule because failure or the detection of a problem of

quality.

Built-To-Order (BTO)

·

Built-to-order

and sometimes referred to as make-to-order (MTO), is a production approach

where products are not built until a confirmed order for products is received.

·

This

approach is considered good for highly configured products e.g. bicycles,

computer servers, or for products where holding inventories is very expensive

e.g. aircraft

E-Commerce Notes

Unit-3

Lecture-8

Call Centre

A call centre or call

center is a centralized office used for the purpose of receiving or

transmitting a large volume of requests by telephone.

Inbound call centre is operated by a company to administer incoming product support or

information inquiries from consumers.

Outbound call centers are operated for telemarketing, solicitation of charitable or political

donations, debt collection and market research.

In addition to a call centre,

collective handling of letter, fax, live support software, and e-mail at one

location is known as a contact centre.

Premise-based Call Centre Technology historically, call centers have been

built on PBX (Private Branch Exchange) equipment

that is owned and hosted by the call centre operator. The PBX might provide

functions such as Automatic Call

Distribution, Interactive

Voice Response, and skills-based routing. The call centre operator would be

responsible for the maintenance of the equipment and necessary software

upgrades as released by the vendor.

Virtual Call Centre Technology With the advent of the Software as a

service technology

delivery model, the virtual call centre has emerged. In a virtual call centre

model, the call centers operator does not own, operate or host the equipment

that the call centre runs on. Instead, they subscribe to a service for a

monthly or annual fee with a service provider that hosts the call centre

telephony equipment in their own data centre. Such a vendor may host many call

centers on their equipment.

Call Centre

Operations

·

Real-time operational

management

·

Process review

and optimization

·

Human resources

(recruiting and general support)

·

Information

technology

Contact

Center Components

There are four main components that make up a contact

center. These components are:

- Telecommunication

Network

- Hardware

- Software

- Infrastructure

Telecommunication

Network

A telecommunication network is essential to connect a

caller with a contact center employee. Generally, the following elements are

needed to establish a telecommunication network:

- Public

Switched Telephone Network (PSTN)

- Router

- Long

Distance Carrier (LDC)

- Ethernet

Switch

- Modem

- Server

Contact

Center Hardware

The hardware needed for a contact center includes a

local area network (LAN), an automatic call distributor (ACD), agent desktops,

computer technology integration (CTI), web integration, and a predictive

dialer. A predictive dialer enables contact centers to handle hundreds of calls

simultaneously.

Contact

Center Software

Important software components include customer

relationship management (CRM) solutions, technical support solutions, and

telemarketing solutions. These solutions help contact center employees manage

customers, resolve and manage technical issues, and provide a means for

marketing. Software is essential to interact with the hardware and

telecommunication network.

Contact

Center Infrastructure

All contact centers have different infrastructures.

Implementing a contact center that provides a return-on-investment (ROI) is a

task that is not always easy to achieve without the right infrastructure.

Businesses that need help building or creating a contact center may want to

consider seeking professional consulting services.

Criticism

and performance

Criticisms

of call centers generally follow a number of common themes, from both callers

and call centre staff.

From

callers, common criticisms include:

- Operators

working from a script

- Non-expert

operators (call screening)

- Incompetent

or untrained operators incapable of processing customers' requests

effectively[18]

- Obsequious

behavior by operators (e.g., relentless use of "sir,"

"ma'am" and "I'd be more than happy to assist you")

- Overseas

location, with language and accent problems

- Touch

tone menu systems and automated queuing systems

- Excessive

waiting times to be connected to an operator

- Complaints

that departments of companies do not engage in communication with one

another

- Deceit

over location of call centre

- Requiring

the caller to repeat the same information multiple times

Common

criticisms from staff include:

- Close

scrutiny by management (e.g. frequent random call monitoring)

- Low

compensation (pay and bonuses)

- Restrictive

working practices (some operators are required to follow a pre-written

script)

- High

stress: a common problem associated with front-end jobs where employees

deal directly with customers

- Repetitive

job task

- Poor

working conditions (e.g. poor facilities, poor maintenance and cleaning,

cramped working conditions, management interference, lack of privacy and

noisy)

- Impaired

vision and hearing problems

- Rude

and abusive customers

So great work for informing us of the possibilities and following a certain path.

ReplyDeleteI really appreciate your hard work an giving us some information and inspiring others to follow.

Thanks so much.

24x7 direct Melbourne

Thanks for sharing this nice information with me.

ReplyDeleteeCommerce Logistics

Thanks for sharing this great information.

ReplyDeleteWeb Design and Development Bangalore | Web Designing Company In Bangalore | Web Development Company Bangalore | Web Design Company Bangalore

Thanks a lot for this great article

ReplyDeleteThanks for sharing wonderful content, its really good for readers

ReplyDeletejio rockers

Hi,

ReplyDeleteThanks for sharing your blog. It was really good. If you're looking for personal storage units then you must consider Spacebox Birmingham. They are committed to providing services to clients that work With 10+ years of experience and a diverse portfolio, Spacebox is able to cater and design services for most businesses.

This comment has been removed by the author.

ReplyDeleteIt is the one of the best blog. Because I get the best information to on your blog. riding round in a rover

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteSuch a nice blog. Its truly amazing information about

ReplyDeleteE-commerce logistics.

E-commerce Unit 3 is a comprehensive module, delving into key strategies. Explore The Best It covers topics from online marketing to payment, Real-world case studies the dynamic e-commerce.

ReplyDelete